| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

| Means of Transport: | Ocean, Air |

| Production Capacity: | 50 |

| Packing: | wooden box |

| Delivery Date: | 25 days |

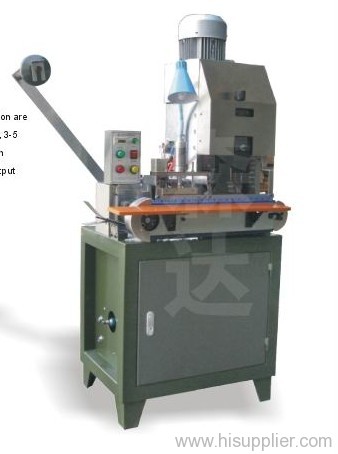

Applicable cable: H03VV-F,H05VV-F (Small than 1.5mm2)

Description of product; with CE mark.

Automatic feed and pressure connection can be completed once for all.Equipped with a protective

Unit on the pressure connection point and it is safe and concenien for operation.

A green hand is easy to be skilled for operation.

Parameter table of product

Model of machine | YH-003A | Pressure connection speed | 600-1000 PCS/Hour |

Punching Force | 3T | Voltage | AC220V/50HZ |

Pressure of air source | 0.5-0.8Mpa | Weight | 250KG |

Dimension | 1250mm*730mm*1550mm | ||

A "terminals crimping machine" is a power-assisted tool designed to permanently join electrical terminals to wires, creating secure electrical connections. These machines use compressed air (pneumatic) or electricity to apply significant, precise force, allowing for efficient, high-quality, and repetitive crimping compared to manual tools. They are available in various configurations, from portable, handheld tools to heavy-duty benchtop models, and are equipped with interchangeable dies or applicators to accommodate a wide range of terminal types and wire gauges.

How it works

Power Source:

The machine is powered by either compressed air, requiring a connection to an air compressor and electricity, or solely by electricity.

Terminal and Wire Insertion:

Wires are stripped and inserted into the appropriate terminal, which is then placed into the machine.

Crimping Action:

The machine's powered mechanism generates force to squeeze the terminal onto the wire, creating a strong and reliable electrical connection.

Interchangeable Dies:

Different dies are used for different terminal shapes (like rings, spades, or butts) and wire sizes, allowing for a wide variety of applications.

Types of Crimping Machines

Pneumatic Crimping Machines:

Use compressed air for high-speed, powerful, and consistent crimps. They are ideal for heavy workloads and offer precise control.

Electric Crimping Machines:

Powered by electricity, these machines provide an alternative to pneumatic systems, requiring only an electrical supply.

Hydraulic Crimping Machines:

While not mentioned in the provided snippets as "pneumatic" or "electric," some powerful heavy-duty crimping tools may use hydraulic pressure for extremely large terminals and heavy gauge wires.

Key Features

Precision:

Powered mechanisms offer greater precision and consistency in crimp quality.

Efficiency:

Automated or power-assisted action significantly speeds up the crimping process.

Versatility:

Interchangeable dies allow a single machine to crimp various terminal types and wire sizes.

Power and Speed:

High-output machines are built for demanding applications with high-volume crimping requirements.

Category: Full automatic crimping machine

Related Category: silicone rubber extruder line High-speed wireline-intertwist machine Multi-wire drawing machine Automatic cable tie twisting machine Injection mould machine